Do you remember the days when printing involved messy ink cartridges, smudged paper, and long wait times? Well, those days are long gone thanks to the revolution of digital printing. Digital printing has completely transformed the printing industry, making it faster, more efficient, and more accessible than ever before. If you’re curious about how this technology is changing the game, keep reading!

In this article, we will explore how digital printing is revolutionizing the printing industry. From its impact on customization and personalization to its environmental benefits and cost-effectiveness, we will delve into the various ways digital printing is transforming the way we print. So, if you’re ready to discover the exciting advancements in the world of printing, let’s dive in!

What Is Digital Printing?

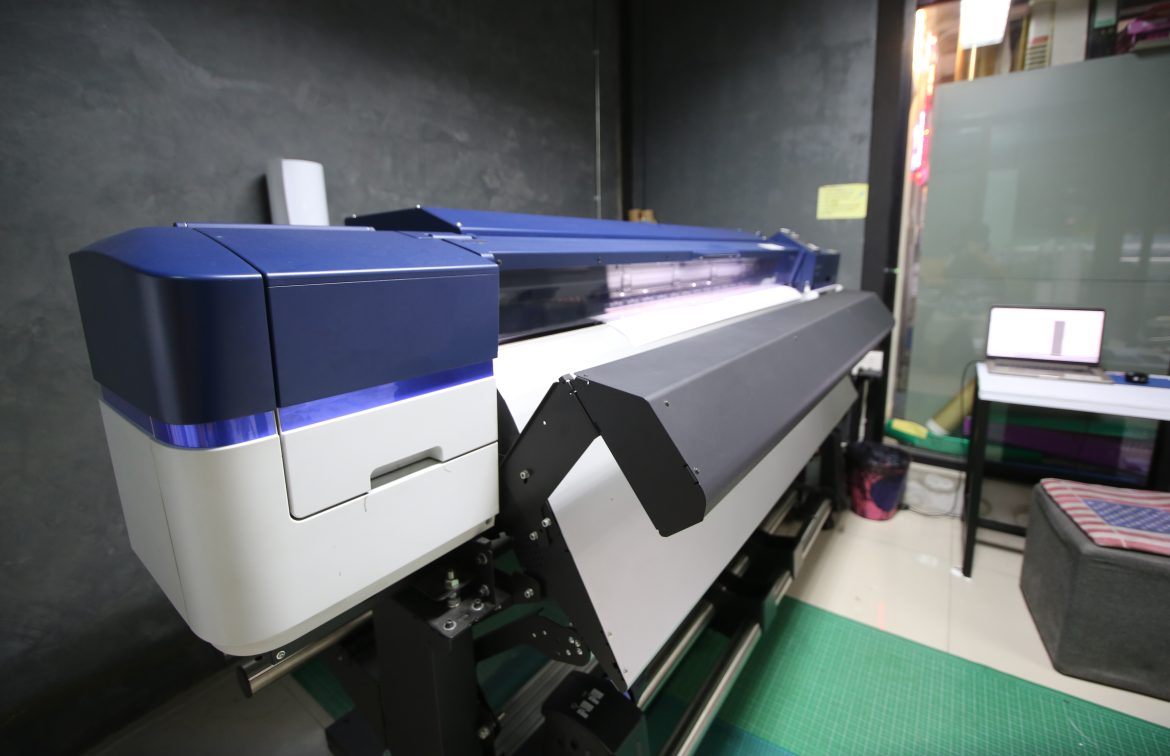

Digital printing is a revolutionary technology that is transforming the traditional printing industry. Unlike traditional printing methods, which rely on physical plates and presses, digital printing utilizes digital files to produce high-quality prints with exceptional precision.

How Has Digital Printing Changed The Print Industry?

Digital printing has revolutionized the print industry in several ways. One of the most significant impacts is the speed at which prints can now be produced. With traditional printing methods, the process often involved complex setup procedures and drying times for the ink. Digital printing, on the other hand, allows for much faster printing speeds, significantly reducing turnaround times.

Another major change brought about by digital printing is the cost savings it offers. Traditional printing methods often required large bulk orders to be cost-effective. This posed a challenge for smaller businesses or those with specific printing needs. Digital printing has made it possible to print smaller quantities economically, allowing businesses to order exactly what they need and reduce unnecessary inventory.

Digital printing has also expanded material options for prints. In the past, traditional printing methods were limited to certain substrates and materials. However, digital printing can now be done on a wide range of materials, including fabrics, plastics, metals, and even three-dimensional objects. This versatility opens up new possibilities for product designs, promotional materials, and personalized products.

Advantages Of Digital Printing Over Traditional Offset Printing

Digital printing offers several advantages over traditional offset printing methods:

Firstly, digital printing provides cost savings. Unlike offset printing, which requires expensive setup fees and large format print runs to be cost-effective, digital printing allows for smaller print jobs at a lower cost. This makes it more accessible for small businesses or individuals with specific printing needs, reducing unnecessary waste and inventory.

Secondly, digital printing offers greater accuracy. Traditional offset printing methods involve multiple steps and the use of printing plates, which increases the risk of human error. In contrast, digital printing eliminates the need for plates and produces flawless prints directly from digital images. This ensures consistent and high-quality prints every time.

Another advantage of digital printing is quick turnaround times. With digital printing, there is no need for lengthy setup times or drying periods. The digital printer can start printing immediately, significantly reducing production time. This allows for faster delivery and shorter lead times, meeting the demands of today’s fast-paced business environment.

Furthermore, digital printing provides the ability to print on a wide variety of surfaces. While traditional offset printing is limited to specific substrates, digital printing can be done on materials such as fabric, plastic, metal, and even three-dimensional objects. This versatility opens up new possibilities for print product designs, promotional materials, and personalized products.

Types Of Digital Printing Technologies Available Today

Today, there are several types of digital printing technologies available that have revolutionized the printing industry.

One popular form of digital printing is inkjet printing. This technology uses tiny droplets of ink that are sprayed onto the printing surface. Inkjet printing offers high image quality and is widely used in the printing industry for a range of applications, including business cards, marketing materials, and promotional products. It is known for its versatility, as it can print on a variety of substrates including paper, fabric, and plastic.

Another important digital printing technology is UV printing. UV printing involves the use of ultraviolet light to dry the ink as it is printed. This results in faster printing times and provides a durable and long-lasting print. UV printing is often chosen for applications that require high image quality and durability, such as signage, labels, and packaging materials.

Lastly, 3D printing is a cutting-edge technology that has transformed the manufacturing sector. This technology creates three-dimensional objects layer by layer using materials such as plastics, metals, and ceramics. 3D printing allows for highly customized and intricate designs, making it ideal for prototyping, product development, and even creating personalized products.

Challenges Faced By The Printing Industry Due To The Emergence Of Digital Technology

The emergence of digital technology has presented several challenges for the printing industry. One of the main challenges is the “race to the bottom.” With the rise of digital printing, competition has increased, leading to price wars among print companies. The ease and accessibility of digital printers have made it easier for new entrants to enter the market, resulting in a downward pressure on prices.

Another challenge is operational visibility. Traditional printing methods often involved complex and time-consuming processes, making it difficult to track and manage production workflow. Digital technology has provided printers with greater operational visibility, allowing them to streamline production processes and improve efficiency.

Spoilage rate is another challenge faced by the printing industry. With traditional offset printing, printers had to set up traditional printing plates for each print job. Any mistakes or errors in the setup process would result in wasted materials and additional costs. Digital printing eliminates the need for setup fees and allows for more accurate printing, reducing the spoilage rate.

The concept of “death by a thousand cuts” also poses a challenge for print companies. As more businesses and individuals turn to digital methods for their printing needs, the demand for traditional print jobs has decreased. Printers are faced with the need to adapt to digital technologies and offer a wider range of services to stay competitive in the industry.

Conclusion

In conclusion, digital printing has revolutionized the printing industry by offering faster, more cost-effective, and flexible printing solutions. With a range of digital printing techniques available, businesses can now easily meet their printing needs and goals.